Tier 4 locomotives pulling for a cleaner future

By SUSAN GREEN

Staff Writer

Transport by rail is the most sustainable way to move goods long distances over land. At BNSF, we take sustainability seriously, and that’s why we have committed to achieving a 30-percent reduction in greenhouse gas emissions by 2030 from a baseline year of 2018.

One of the ways we’ll achieve this goal is by continuing to improve the fuel efficiency of our locomotives, which need to work in all types of weather and rugged conditions while providing dependable heavy-haul motive power. In honor of Earth Day, we look at our Tier 4 locomotives, one in a series of “Evolution” locomotives that are the newest and cleanest-burning locomotives in North America.

“Wabtec’s Tier 4 locomotives are a compelling sustainable solution for BNSF,” BNSF Vice President of Environmental John Lovenburg said. “The locomotives reduce operating costs with higher reliability, more tractive effort and improved fuel efficiency. Better fuel efficiency also reduces greenhouse gas emissions."

For nine years, BNSF has purchased Tier 4 locomotives from Wabtec (formerly General Electric Transportation Systems). Tier 4s, the latest of the Evolution Series locomotives, are designed to reduce criteria pollutant emissions by 70 percent over standard locomotives.

To understand the development of this series requires a look back. In 1998, the Environmental Protection Agency (EPA) adopted its first locomotive emissions standards. Between 2000 and 2005, emissions standards for Tier 0 to Tier 2 locomotives went into effect, and in 2008, the EPA defined Tier 3 and Tier 4 locomotive standards. At each stage, emissions standards became stricter. In 2015, the first Tier 4 production model was delivered to BNSF.

Today, these 432,000-pound 6-axle giants deliver 4,500 horsepower and can reach maximum operating speeds of 75 mph pulling thousands of tons of freight. Another impressive number: Tier 4s produce more than 90 percent less particulate matter and oxides of nitrogen (NOx), a major ingredient in producing smog and ozone, than earlier locomotive models.

Tier 4s also use AC (alternating current) motors that provide higher tractive effort, advanced traction control, require less maintenance and are more reliable compared to early models equipped with DC (direct current) motors.

BNSF now has 352 Tier 4 units with another eight to be delivered in May, and roughly 65 percent of our fleet is Tier 3 or better.

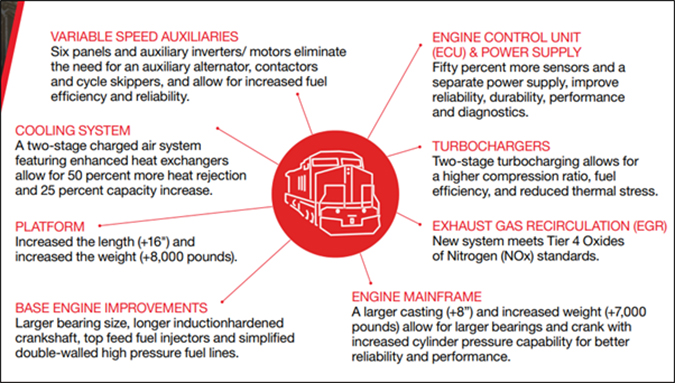

Externally, the Tier 4 units look the same as any other Wabtec locomotive on the BNSF system. The differences are under the hood. The biggest difference is the fuel system, which uses high-pressure common rail fuel system technology, similar to what’s been in place on truck and off-road diesel engine applications for years. A common rail fuel system maintains a continuous supply of fuel at a high constant pressure, which provides more flexibility in fuel injection control and better atomization, resulting in cleaner, more efficient combustion.

What’s most notable about Wabtec’s Tier 4 locomotives is they don’t use any type of after-treatment or Diesel Exhaust Fluid (DEF), which would have required the addition of a large on-board reservoir. It would also have meant railroads would have to supply millions of gallons of DEF – and ensure that they never ran out of it.

“As an industry, we needed an in-engine solution, rather than having to adapt the storage system on a locomotive, which would have significantly changed its size and necessitated a change to our fueling infrastructure,” explained Keith Solomons, BNSF vice president of Mechanical.

Instead of going with the after-treatment concept, Wabtec created a solution called Exhaust Gas Recirculation (EGR). EGR works by routing, cooling and feeding a controlled amount of exhaust gas – about 10 percent -- created during combustion back into the locomotive engine’s intake air system. This process dilutes the air and fuel mixture that enters the combustion chambers, which reduces the engine’s peak combustion temperature.

Among the new features of the latest Tier 4 models is the Advanced Rail Cleaning (ARC) system, which helps to remove rail contamination such as moisture, snow and debris.

“Today we use our Tier 4s in all parts of our system and in all types of service,” Solomons said. “When we made the decision to go with buying new Tier-4s, it was strategic because we knew that by buying new, we’d be buying the cleanest operating, most fuel efficient and most reliable locomotive available rather than remanufacturing existing older vintage locomotives.”

With proper maintenance and use, these Tier 4 locomotives will be hauling freight until at least the 2050s. More importantly, they’ll meet the most rigorous air quality standard to date for locomotives, improving air quality – something for which we can all breathe easier.